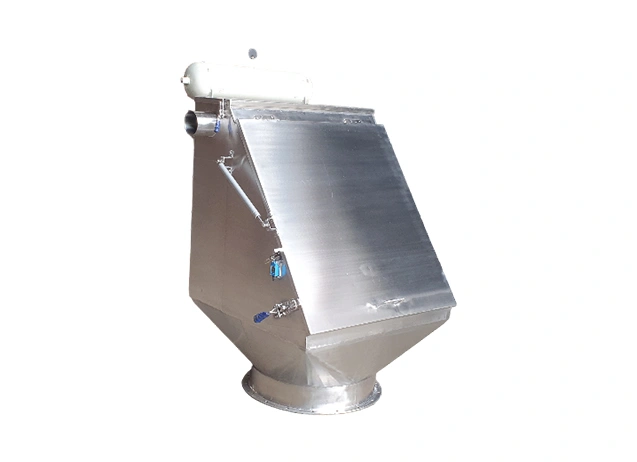

Bag Dump Station

Varahi Industries’ Bag Dump Station integrates manually-emptied dry bulk materials into blenders, agitator hoppers, storage bins, size reduction machines, and pneumatic conveying systems—while minimizing product loss and dust generation.

An ergonomic enclosure lets operators safely open and empty bags. Dust released during tipping is captured by the integrated dust collection system (centrifugal blower + automatic reverse pulse-jet filter) and returned to the process—improving recovery, reducing contamination, and mitigating explosive dust risks.